What You Need To Know

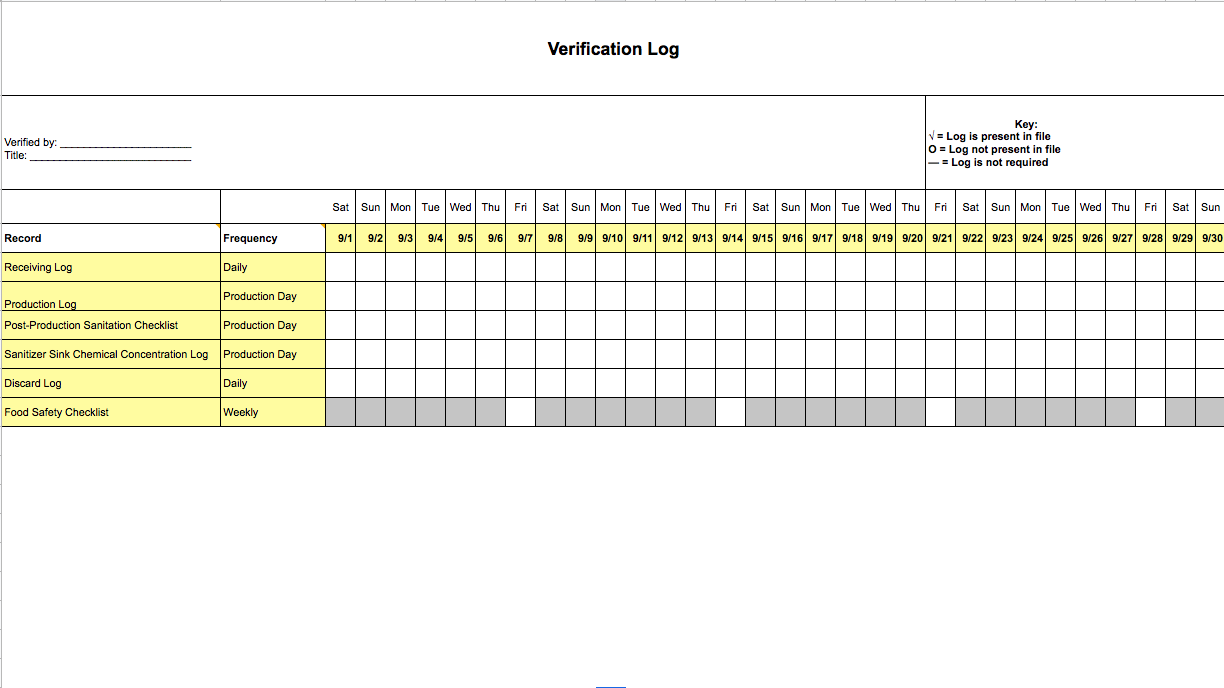

Part 117 Subpart F contains the requirements for record keeping

Keep all of your records related to your food safety lan.

Records can be electronic or paper.

You must store records onsite for at least 2 years

All records must be made available upon request

Record Keeping Requirements

How Records Must Be Kept

Records must be kept as originals, true copies (i.e. scans, photocopies) or electronic records.

They must contain the actual values and observations, not summaries.

They must be accurate, unchangeable (i.e. pen) and legible

They must have been created in real-time with the activity being documented.

Required Information on All Records

The following information is required on all records you keep:

information about the plant identity

The date (and time, if necessary)

Signature or initials of the observer

Product name and lot code, if applicable

How long do I need to keep them for?

All records must be retained onsite for 2 years. Additionally, you must be able to retrieve records within 24 hours if an authorized request is made.

Looking for More?

Check out our comprehensive guide to Part 117 Subpart F, Record Keeping or the FDA Reader Complete Guide to FSMA

This Article is For You if…

∆ You take any records as part of your food safety plan

∆ You are developing a food safety plan or HACCP plan.

∆ You are any type of FDA regulated food business

All of our food safety plan templates are aligned with this section.